Creating Tailored Applications Across Diverse Manufacturing Scenarios with Advantech iFactory

1/1/2567

According to the Food and Agriculture Organization (FAO) of the United Nations, one-third of global food production is lost or wasted each year. Developing countries in particular experience significant food losses throughout the production chain, with an estimated 30–40% of total production being lost before reaching the market. It is critical to recognize that this loss also results in the waste of all energy and resources invested in food production.

Smart manufacturing technologies offer a promising solution for optimizing food production processes in developing countries. Such technologies can enhance efficiency, quality control, and traceability, thus reducing waste. Eforel, one of Advantech’s domain-focused system integrators (DFSI) specializing in industrial IoT, is now introducing smart manufacturing computing platforms and software applications through Advantech’s iFactory Solution Ready Packages to promote sustainability and contribute to developing more efficient and resilient food systems in Indonesia.

Solving management concerns with real-time monitoring

Headquartered in the US and with numerous factories around the world, a multinational food products corporation leveraged Eforel’s expertise to spearhead the digital transformation of its factory in Indonesia after recognizing the significance of smart manufacturing in enhancing operational visibility, reducing costs, improving efficiency, and optimizing production.

At the forefront of their concerns were critical management responsibilities such as tracking machine operation times and downtime, monitoring production capacities and quality, and conducting root cause analysis for abnormalities. Mr. Hanggar Cahya Kusuma, CEO of Eforel, pointed out, “Unfortunately, these tasks were being carried out manually, resulting in unexpected drawbacks. The manual production of reports led to inaccurate equipment records with frequent human errors.”

During the project’s proof-of-concept phase, Eforel proposed leveraging Advantech’s iFactory/OEE solution, which incorporates various components that help achieve their objectives. First, they suggested implementing the MIC-7700 compact fanless on-premises OEE server to enable the processing of real-time production data with intuitive management dashboards as well as data analysis and visualization capabilities.

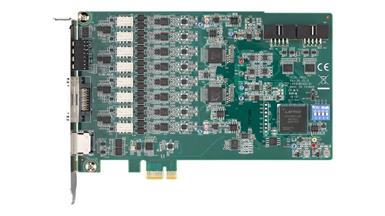

Second, ECU-1051 IoT gateways were recommended to connect PLCs on production machines such as mixers and fillers. ADAM-6051 I/O modules were also proposed for machines without PLCs, such as palletizers. Both the ECU-1051 and ADAM-6051 enabled seamless integration into the OEE system.

To ensure comprehensive coverage across the installation site, multiple EKI-6333AC wireless access points were installed to achieve stable data transmission. These devices simplified the installation process as they do not require extensive cabling or machine modification. Additionally, Eforel supplied dedicated tablets equipped with tailored user-friendly software specifically designed for gathering maintenance data from the machines’ CAN interface. This streamlined approach allowed for efficient collection of service reports, which can be promptly submitted to management following each check-up.

OEE solution reduces downtimes, decreases material waste, and increases ROI

Integrating multiple PLC and sensor protocols has always been a significant challenge in factory upgrades and digitalization projects. However, Advantech offers solutions that enable seamless connectivity across different machines. To cater for the food corporation’s unique raw material requirements, Eforel leveraged iFactory’s open architecture and no-code development environment to customize applications to their specific needs.

Eforel were highly praised for implementing Advantech’s iFactory/OEE solution by the food corporation. Real-time data acquisition and analysis provided accurate records of uptime, downtime, production quantity, and machine errors, revealing valuable insights via intuitive dashboards that allowed management to promptly take corrective actions when necessary. This significantly reduced the waste of raw materials, water, and energy that had previously resulted from machine errors. Service reports also enabled supervisors to identify the root causes of machine errors, shorten maintenance times, improve utilization rates, identify production bottlenecks, plan preventative strategies, and ultimately maximize ROI.

Following a successful proof of concept involving 20 machines, the food corporation intends to deploy iFactory OEE and Statistical Process Control on other types of machines in the factory. This expanded implementation aims to provide production visibility, improve efficiency, optimize resources, enhance standard operating procedures, and bolster quality control.

In anticipation of the future, Mr. Hanggar Cahya Kusuma, the innovative mastermind driving this project, envisions embarking on numerous benchmark projects across diverse manufacturing scenarios. Eforel has already compiled an extensive collection of statistical data from past projects, showcasing impressive improvements in quality, performance, ROI, and other key metrics. To meet the unique demands of individual scenarios, Mr. Kusuma plans to create industry-specific software packages rooted in iFactory. This strategic approach is expected to enhance their reputation among international manufacturers operating in Indonesia.

Case Study Benefits

- Improved production visibility and efficiency

- Identification of the root causes of downtimes and machine errors

- Shortened maintenance times and increased utilization rates

Solution Benefits

The intuitive no-code development environment in Advantech’s iFactory streamlines the application creation process. This revolutionary approach eliminates the need for extensive programming knowledge, allowing system integrators to focus on delivering exceptional results and exceeding manufacturers’ expectations.

WISE-IoT Magazine – Intelligent Factory: Transformation the Global Manufacturing Landscape with IoT

Advantech has remained committed to collaborating with global partners. Together, we strive to develop solutions that facilitate the rapid digital transformation of manufacturing while boosting competitive advantage.

-25/Project_02--_Vertical20220406173334.jpg)